Streamlining your Path from R&D to High Yield Production for IR Thermal Imaging Devices

Our FINEPLACER® die bonder systems help you achieve manufacturing autonomy and remove supply chain dependencies.

Lean on expert support and guidance throughout the entire development process and ensure your IR thermal imaging devices reach the market faster without compromising on quality, risks and costs.

Are you a business specializing in hybridization products seeking a smooth transition from R&D to production while ensuring IP protection?

Are you a business specializing in hybridization products seeking a smooth transition from R&D to production while ensuring IP protection?

The leap from R&D to production is often fraught with challenges, including high costs, risks of failure, and potential IP vulnerabilities.

At Finetech we offer comprehensive solutions that streamline the transition of hybridization products from R&D to high-yield production.

Our method is designed to work with minimal, non-sensitive details about the product, focusing on a standardized approach for tooling, process parameters, and application requirements. This allows you to keep intellectual property confidential while still achieving successful results.

The leap from R&D to production is often fraught with challenges, including high costs, risks of failure, and potential IP vulnerabilities.

At Finetech we offer comprehensive solutions that streamline the transition of hybridization products from R&D to high-yield production.

Our method is designed to work with minimal, non-sensitive details about the product, focusing on a standardized approach for tooling, process parameters, and application requirements. This allows you to keep intellectual property confidential while still achieving successful results.

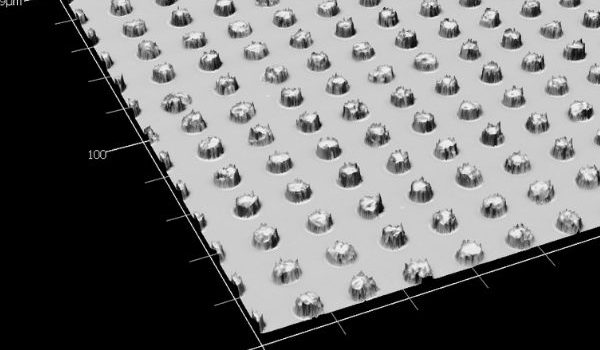

Innovation in Compound Semiconductor Devices

CSA Catapult is the UK’s authority on compound semiconductor applications and commercialization. Finetech could help with a demanding IR Thermal Imaging Device application in defense & security without CSA Catapult disclosing any IP information.

What does our standardized solution entail?

Rapid Transition to High-Yield Production

Our standardized approach allows for a quicker and more efficient transition to high-yield production, ensuring that your product reaches the market faster without compromising on quality.

Standardized Process Implimentation

Our solution implements a standardized yet adaptable process framework, ensuring consistency and reliability in production while accommodating the unique needs of your hybridization project.

Expert Guidance and Support

Our team of experts can provide support and guidance at any point or throughout the entire development process, ensuring that every step is optimized for success.

Minimal Information Requirement

With a stringent focus on using non-sensitive data and respecting IP boundaries, our solution ensures that your intellectual property remains secure throughout the development process.

Have full control of your product development

Achieve manufacturing autonomy and break away from supply chain dependencies. Enhance control and efficiency in-house. Our solutions enable you to reach your goals confidently and effectively.

Cost Reduction and Risk Mitigation

By using standardized and qualified parameters, we significantly reduce the costs and risks typically associated with scaling up from R&D to production.