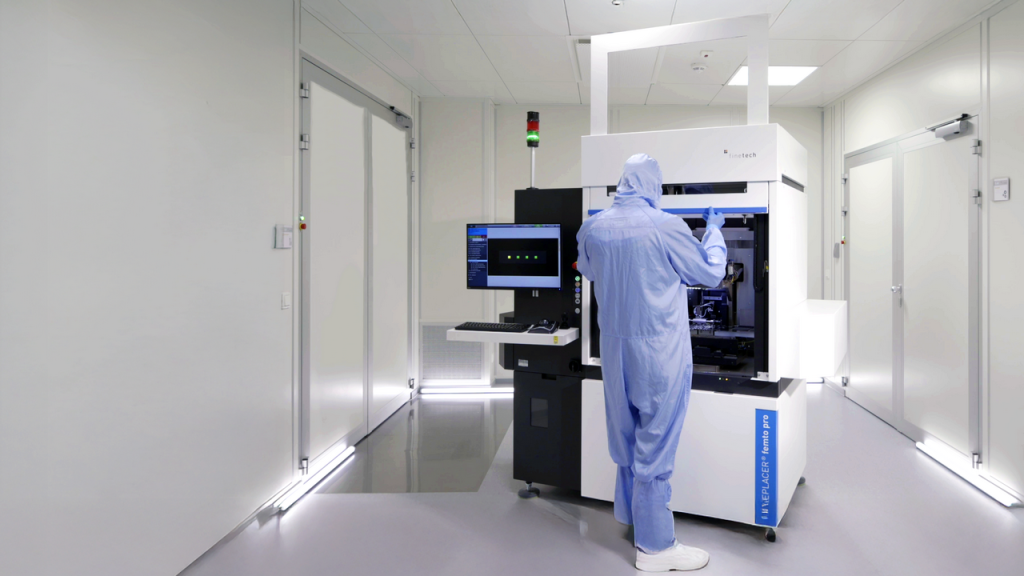

Georgia Tech Packaging Research Center has selected Finetech’s semi-automatic FINEPLACER® matrix bonder to demonstrate the first manufacturable, low-temperature, ultra-fine pitch copper interconnections and assembly technology.

Finetech was selected by the Georgia Tech Packaging Research Center (PRC) to provide it’s semi-automatic FINEPLACER® matrix bonder to demonstrate the first manufacturable, low-temperature, ultra-fine pitch copper interconnections and assembly technology.

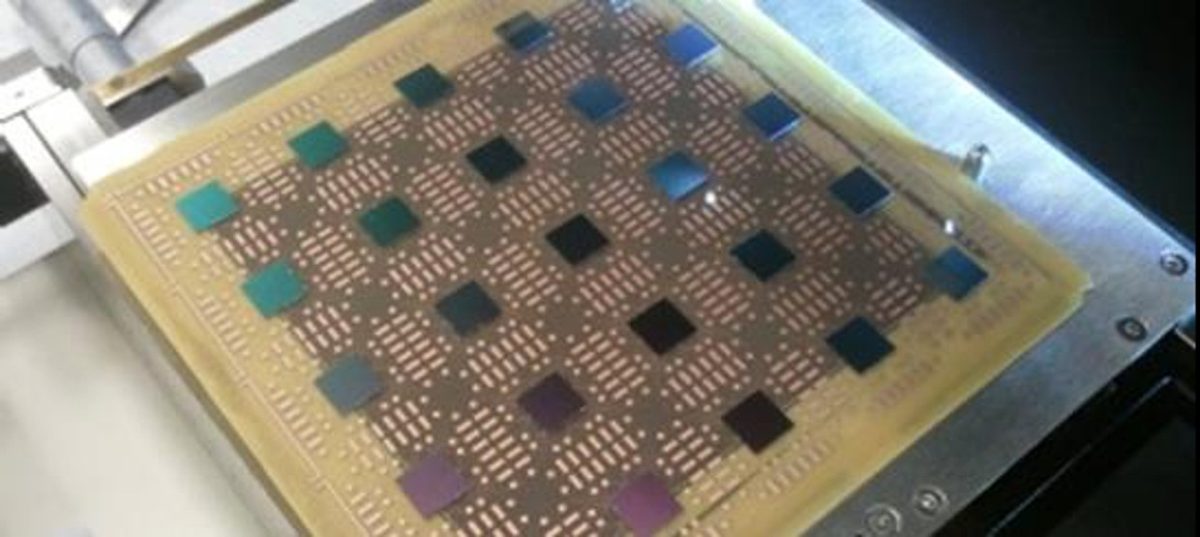

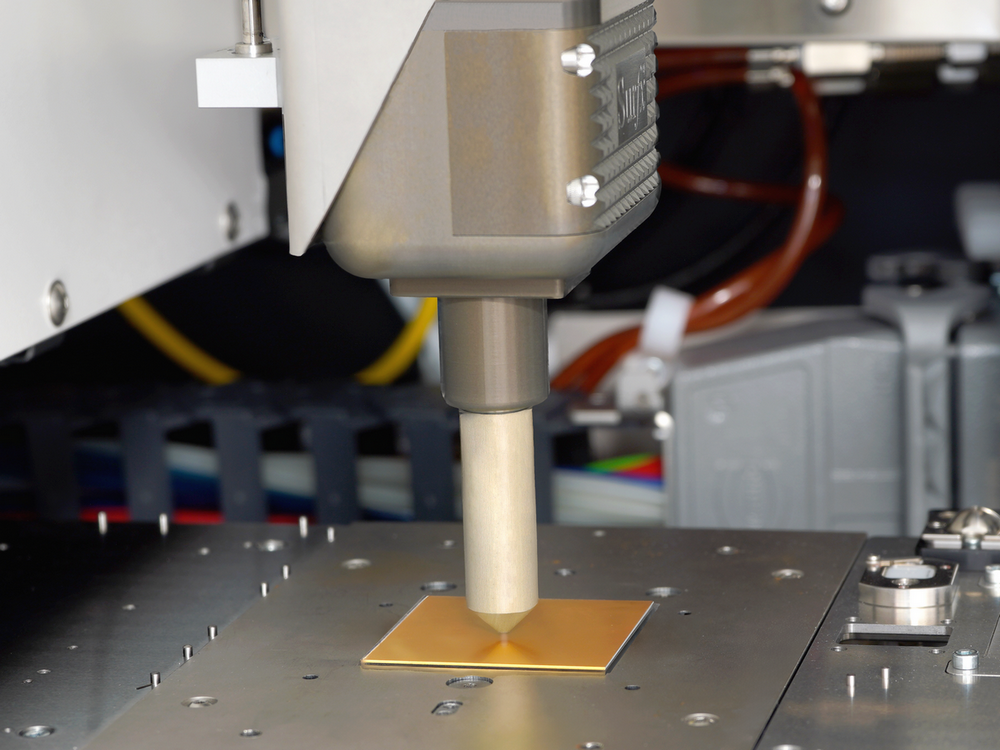

The new Georgia Tech patented technology enables, for the first time, the ability to manufacture reliable copper interconnections at temperatures below 180°C. The process provides tolerance of bump co-planarity and substrate warpage, as well as surface roughness, to achieve ultra-fine pitch interconnections down to 30 µm.

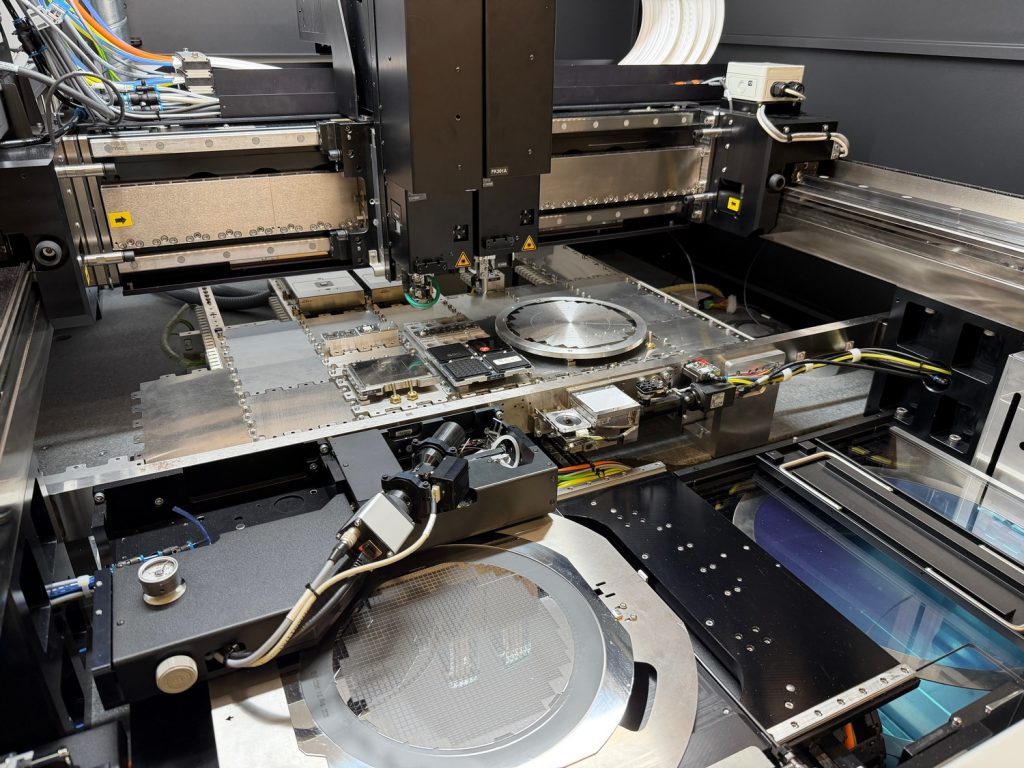

The Finetech FINEPLACER® matrix bonder facilitates Georgia Tech’s research needs by featuring a proven placement accuracy of 3 micron, component size handling from 0.1 mm x 0.1 mmto 150 mm x 150 mm, substrate sizes up to 350 mm x 350 mm or 12″ wafer. A modular design, and real-time contrast optimization with LED lighting, help to make the matrix a low maintenance, flexible, easy-to-use system for R&D, prototype and multi-shift production.

„We have worked with Finetech bonders for many years and selected the new FINEPLACER® matrix platform for our next generation of research and development at the PRC,“ says Dr. Vanessa Smet, the Program Manager for Interconnections and Assembly at Georgia Tech PRC. „The flexibility of the system to handle various bonding conditions, with large array of components and in panel form while maintaining co-planarity and 3 micron placement accuracy, was a very good fit for our research needs. Georgia Tech will present its findings using this tool at Electronic Components and Technology Conference (ECTC) in Orlando in May 2014.“