- We have achieved a breakthrough in microLED manufacturing, reaching an initial yield above 85%.

- Together, we developed a cold compression bonding process with tight process parameter control, specifically tailored for ultra small microLED integration

- This milestone marks a major step toward scalable, high-brightness, full-color microLED display production.

Polar Light Technologies (PLT), a Swedish startup, is pioneering ultra-compact microLED displays using a novel bottom-up GaN growth method. This enables brighter, more efficient emitters with near-perfect surfaces.

To meet the extreme requirements for submicron alignment and ultra-low force bonding, PLT partnered with Finetech to develop a cold compression process — laying the groundwork for scalable, high-yield production of high brightness, full-color microLED displays.

PLT improves AR system efficiency by 50 to 200 times

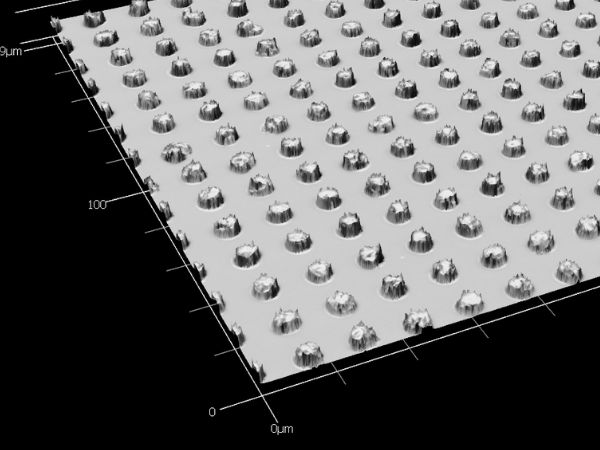

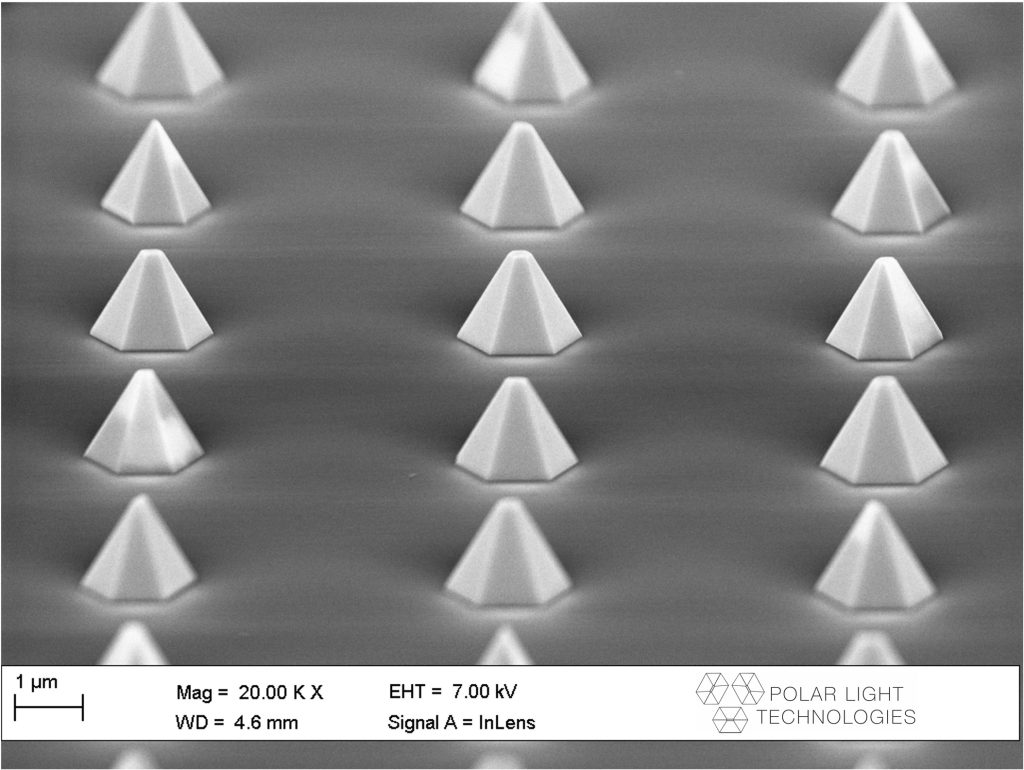

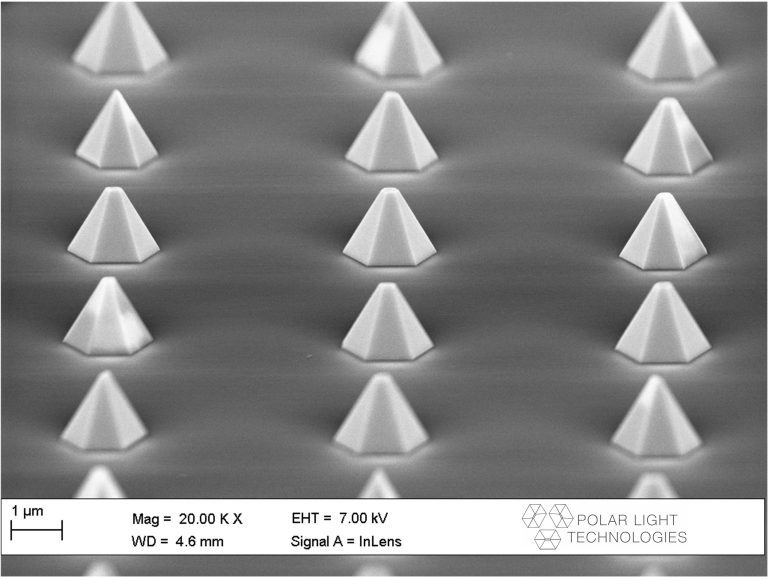

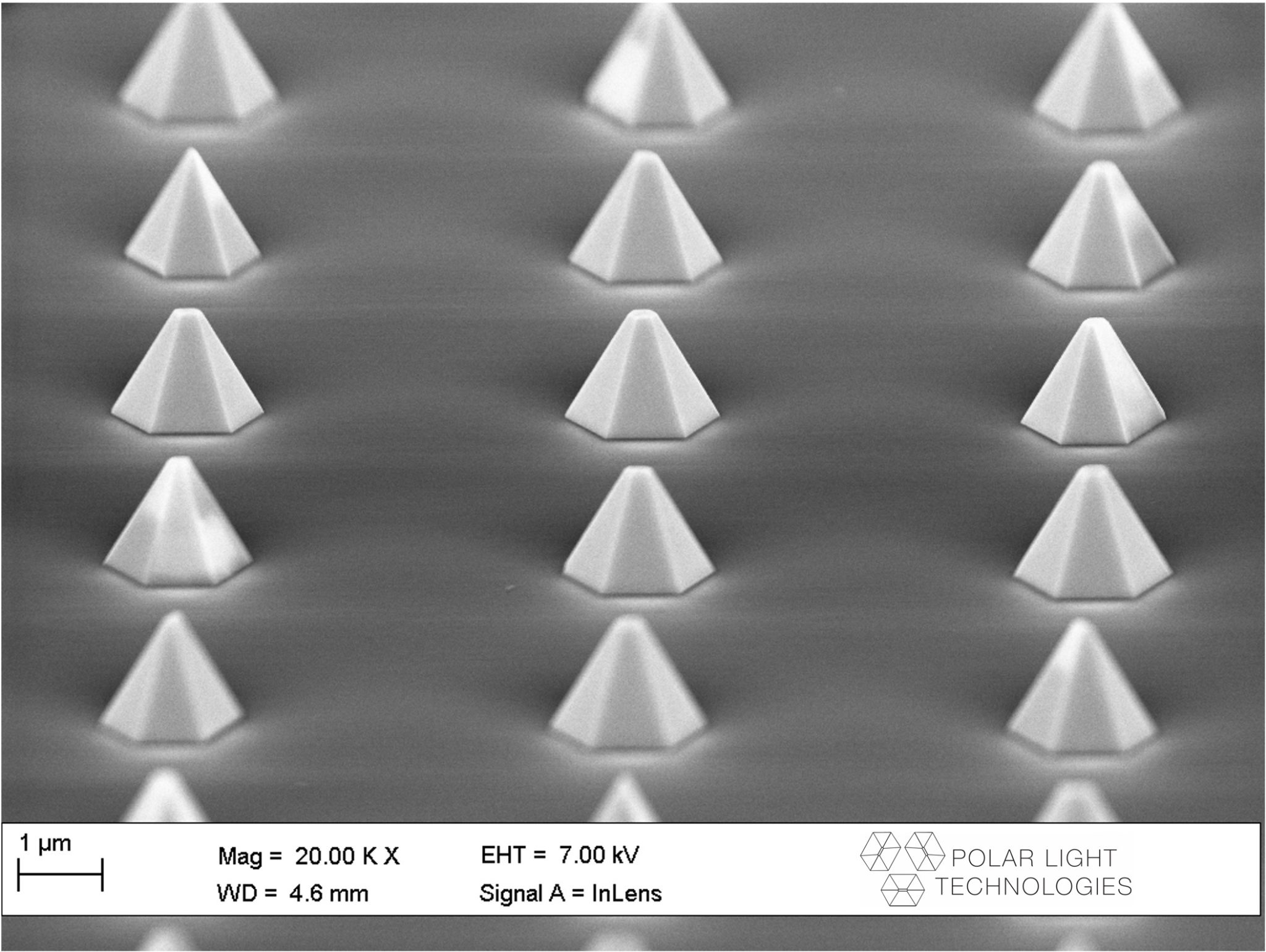

PLT is transforming display technology with its patented bottom-up MOCVD process, growing GaN pyramidal microLEDs directly on SiC substrates using atomic layer regrowth. The process produces microLEDs as small as 300 nm with pristine surfaces and efficient RGB emission from a single GaN-based material system — aiming to solve the industry’s challenge of efficient red-light generation.

These microLED displays can deliver TV-level resolution in less than 5 mm², with pixels spaced just 5 µm apart, and improve AR system efficiency by 50 to 200 times compared to conventional LEDs.

The Integration Challenge

Integrating PLT’s ultra-small microLEDs required extreme precision. With miniaturized chips, micron pitches, and delicate bump structures, traditional bonding systems lacked the accuracy and control needed.

PLT faced tight post-bond accuracy demands, including sub-micron XYZ alignment, ultra-low bonding force, flatness, and parallelism between chip and substrate.

Their challenge was to establish a repeatable, error-free bonding process capable of supporting reliable prototyping and future production at scale.

The Finetech Solution

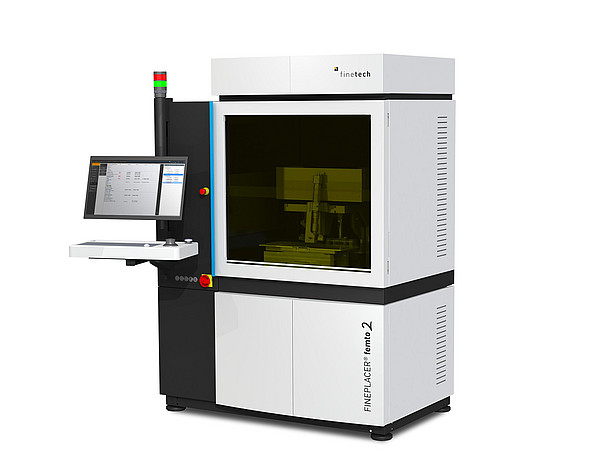

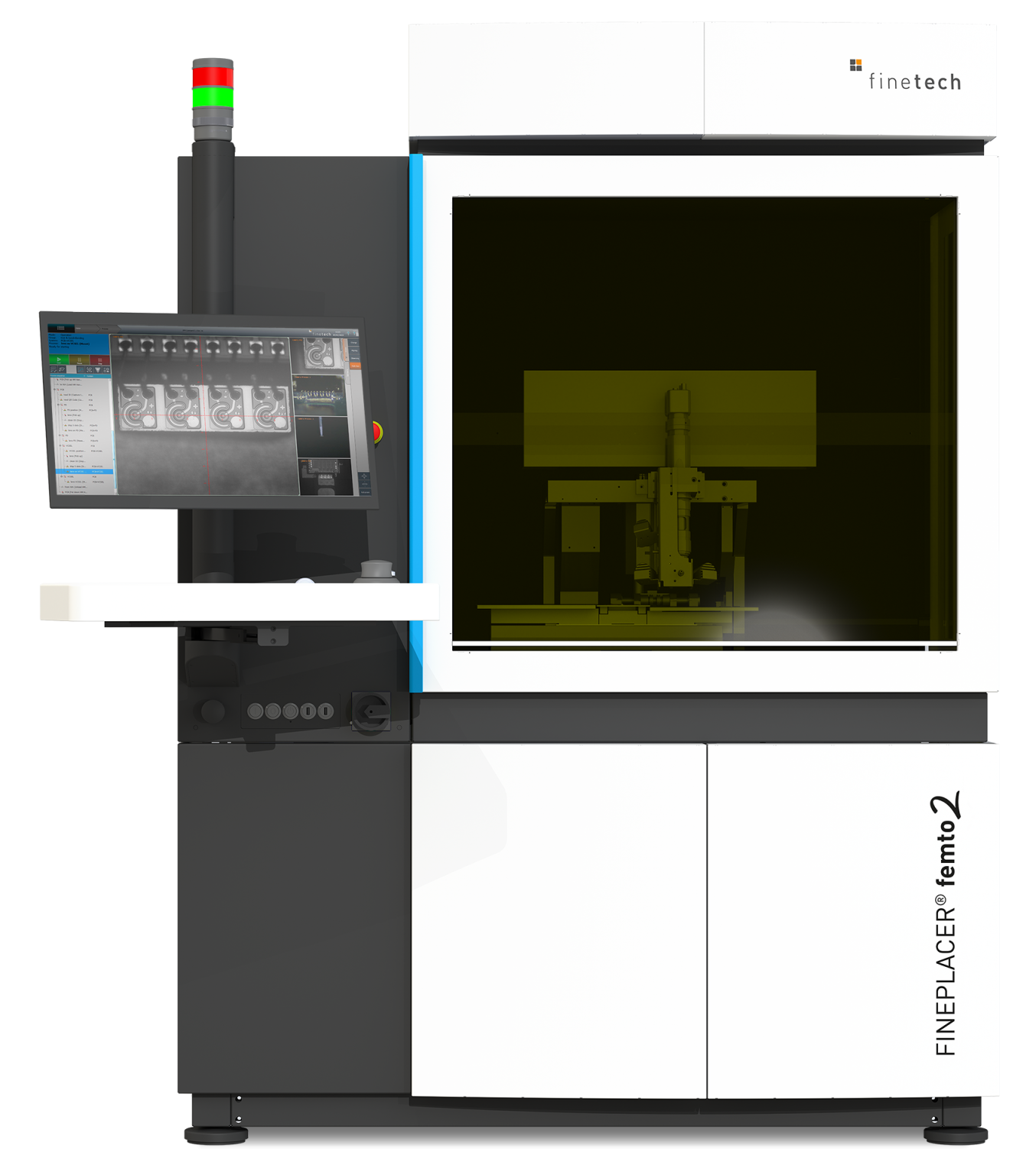

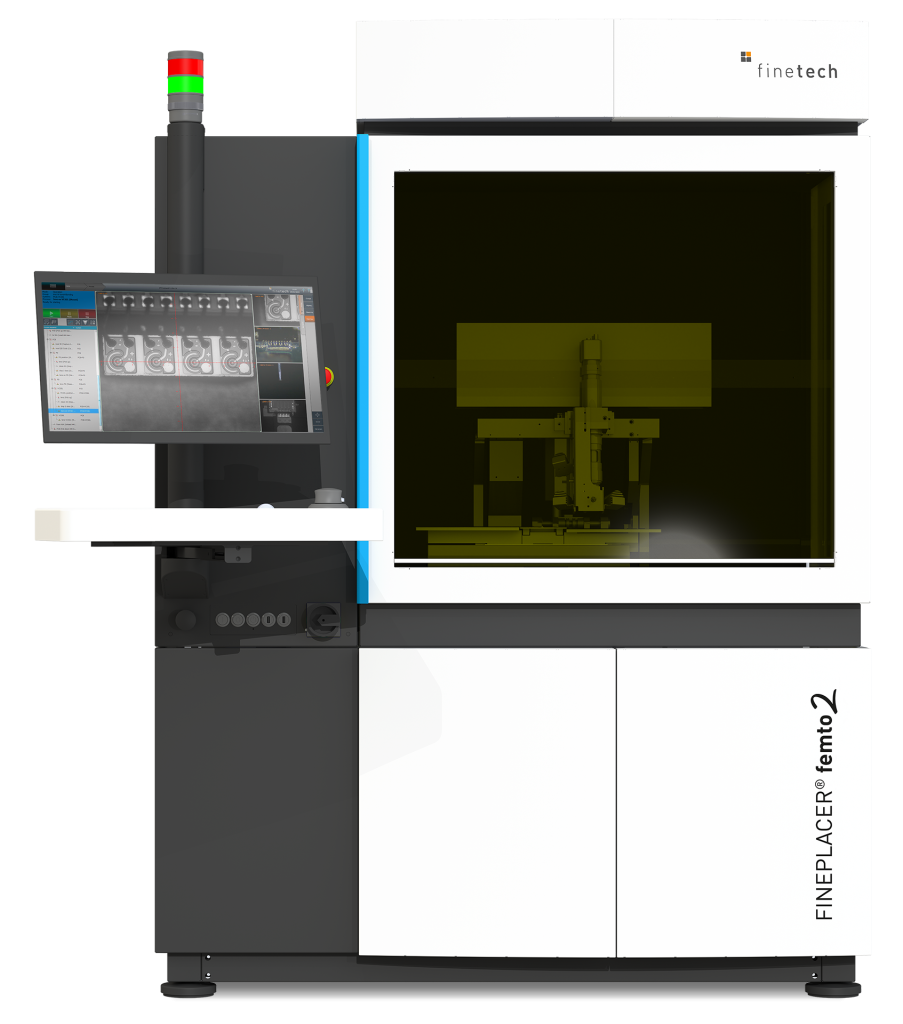

To meet these demands, we supported PLT with process expertise and access to the FINEPLACER® femto 2 automated sub-micron die bonder. Together, we developed a cold compression bonding process with tight process parameter control, specifically tailored for ultrasmall microLED integration:

- Sub-micron XYZ alignment of GaN pyramids to Indium pads

- Room-temperature compression bonding to avoid thermal stress

- Ultra-low bonding force for sensitive microLEDs

- High surface flatness to ensure consistent bondline thickness

- Optional plasma or chemical pre-bond cleaning

- Non-contact handling of delicate bump arrays

This setup allowed PLT to validate its integration method and move forward without immediate system acquisition — benefiting from our experience in supporting advanced optoelectronic assembly.

Reliable MicroLED Integration with <85% Initial Yield

Our collaboration enabled the reliable integration of ultra-small microLEDs, achieving an initial yield above 85%.

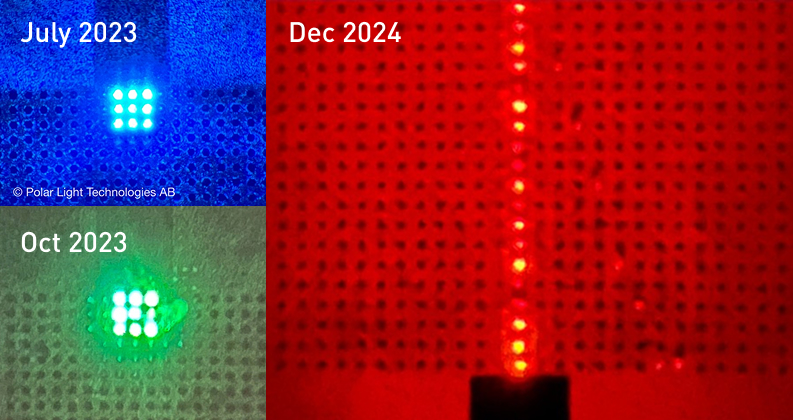

In 2025, PLT publicly demonstrated its first micro-display prototype based on patented GaN/InGaN pyramidal microLEDs.

With Finetech’s precision equipment and process control validating the integration approach, PLT is now moving from lab development to pilot production.

The next phase focuses on improving pattern recognition, adapting tooling for varied chip formats, and scaling to batch bonding — while maintaining sub-micron precision — to enable stable, high-yield production of next-gen displays for AR/VR, wearables, and ultra-high-resolution applications.

Ready to take your die attach to the next level?

The Integration Challenge

Integrating PLT’s ultra-small microLEDs required extreme precision. With miniaturized chips, micron pitches, and delicate bump structures, traditional bonding systems lacked the accuracy and control needed.

PLT faced tight post-bond accuracy demands, including sub-micron XYZ alignment, ultra-low bonding force, flatness, and parallelism between chip and substrate.

Their challenge was to establish a repeatable, error-free bonding process capable of supporting reliable prototyping and future production at scale.

The Finetech Solution

To meet these demands, we supported PLT with process expertise and access to the FINEPLACER® femto 2 automated sub-micron die bonder. Together, we developed a cold compression bonding process with tight process parameter control, specifically tailored for ultrasmall microLED integration:

- Sub-micron XYZ alignment of GaN pyramids to Indium pads

- Room-temperature compression bonding to avoid thermal stress

- Ultra-low bonding force for sensitive microLEDs

- High surface flatness to ensure consistent bondline thickness

- Optional plasma or chemical pre-bond cleaning

- Non-contact handling of delicate bump arrays

This setup allowed PLT to validate its integration method and move forward without immediate system acquisition — benefiting from our experience in supporting advanced optoelectronic assembly.

Impact: > 85 % Initial Yield

Our collaboration enabled the reliable integration of ultra-small microLEDs, achieving an

initial yield above 85%.

In 2025, PLT publicly demonstrated its first micro-display prototype based on

patented GaN/InGaN pyramidal microLEDs.

With Finetech’s precision equipment and process control validating the integration

approach, PLT is now moving from lab development to pilot production.

The next phase focuses on improving pattern recognition, adapting tooling for

varied chip formats, and scaling to batch bonding — while maintaining sub-micron

precision — to enable stable, high-yield production of next-gen displays for AR/VR,

wearables, and ultra-high-resolution applications.

Polar Light Technologies and Finetech have achieved a breakthrough in microLED manufacturing, reaching an initial yield above 85%. This milestone marks a major step toward scalable, high-brightness, full-color microLED display production.